MZG 1pcs CNC Lathe Machine 16 20 25mm Square Bar Extractor Turning Boring Tool System

1. MZG turning tools item specifications

Specification parameters of MZG turning tools

2. Product photo of MZG turning tool

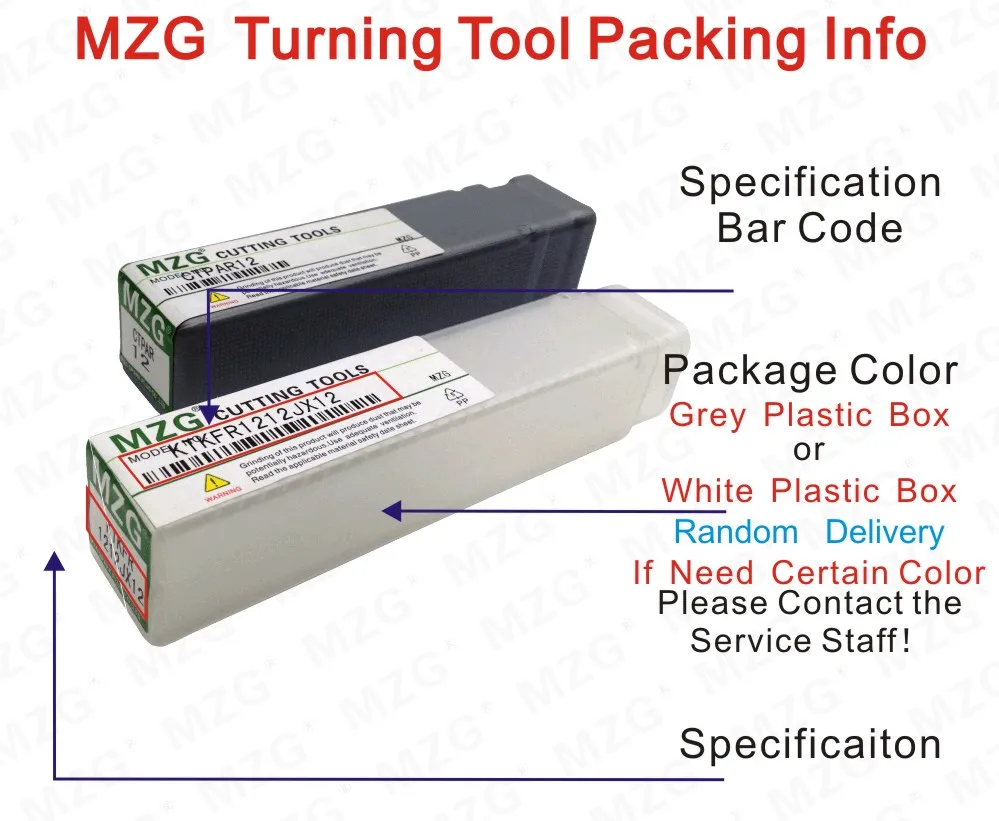

3. MZG turning tool packing information

Turning Tool Packing Information

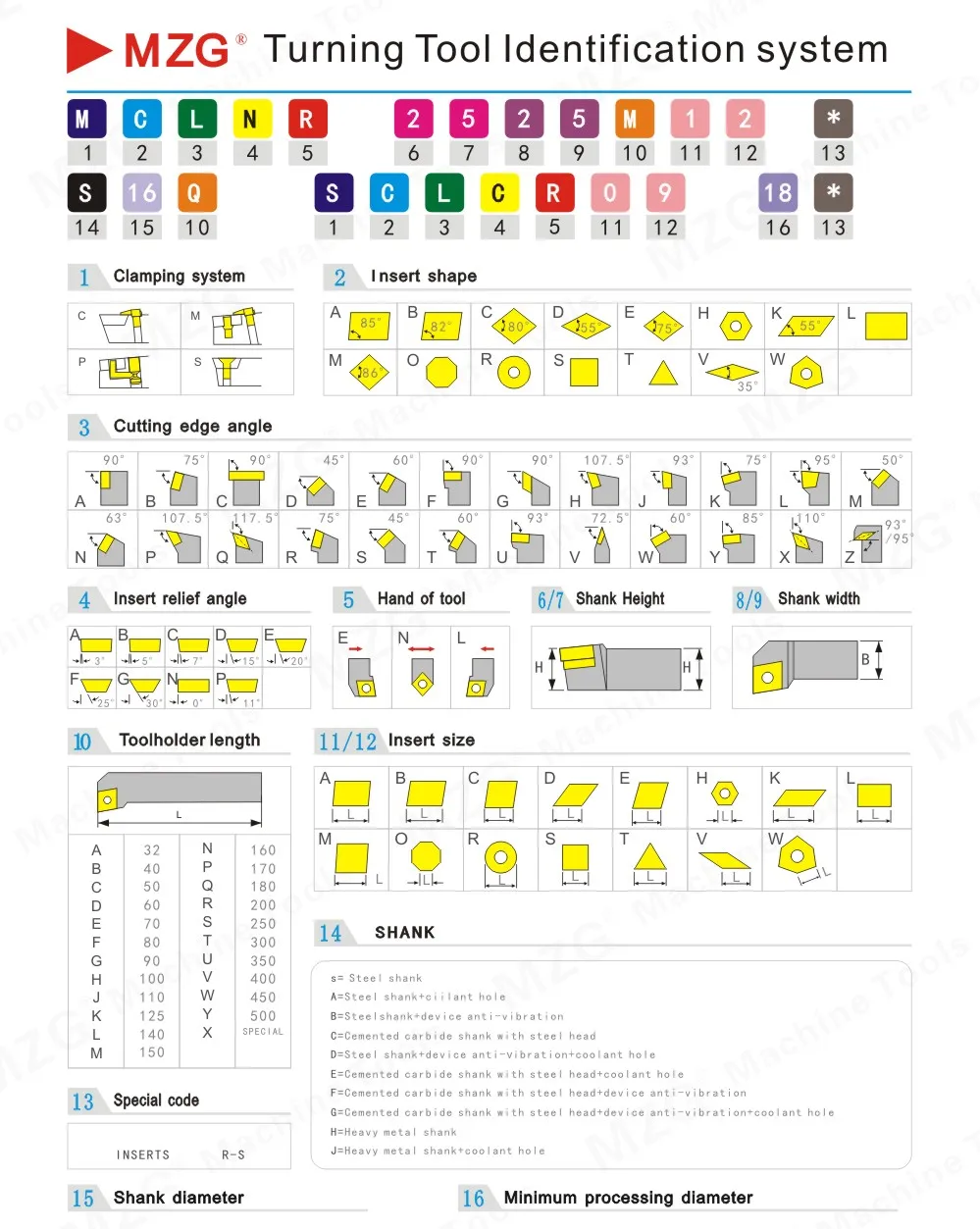

4. MZG turning tool parameter

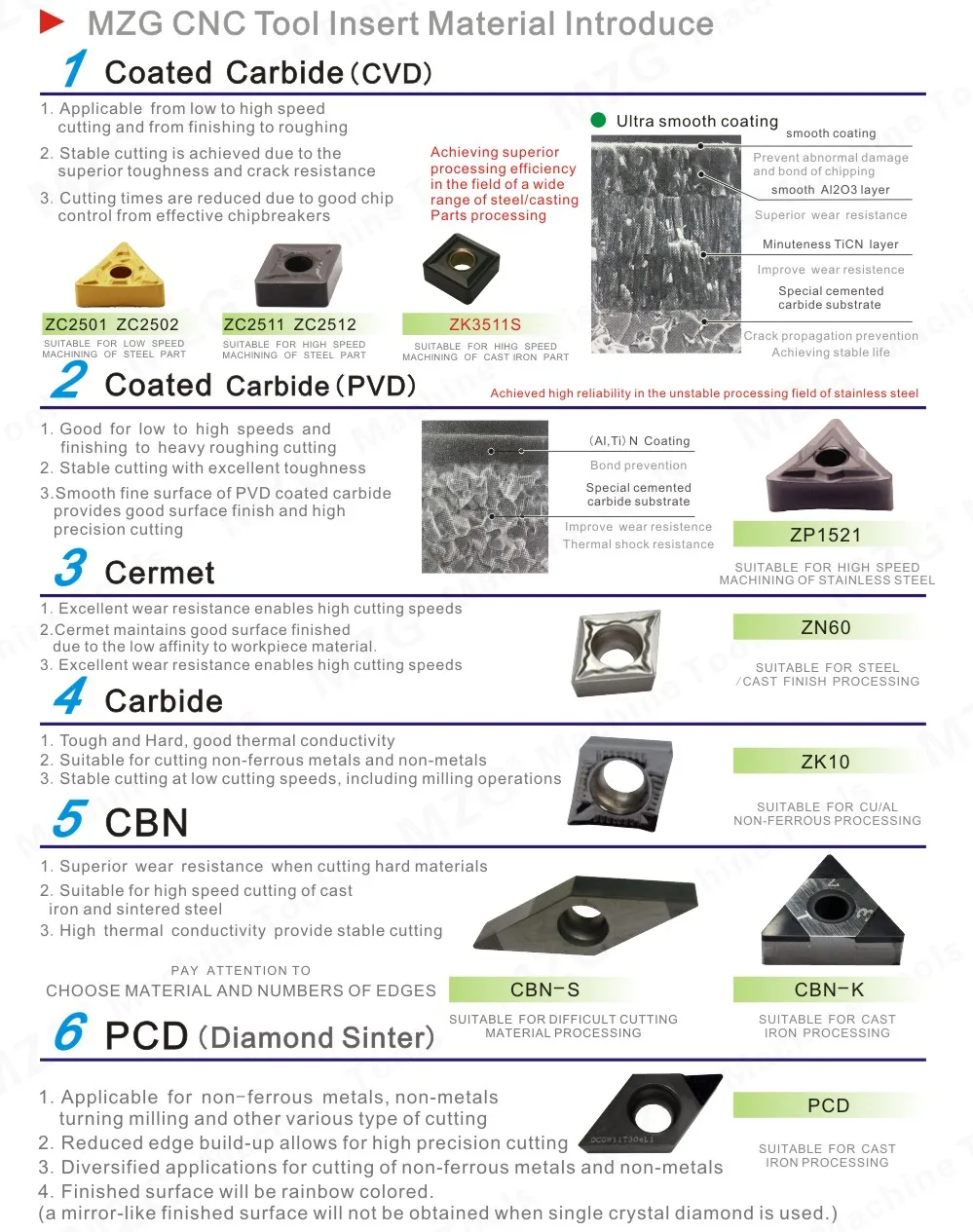

MZG CNC Tool Insert Material Introduce

1. Coated Carbide (CVD)

Applicable from low to high speed cutting and from finishing to roughing.

Stable cutting is achieved due to superior hardness and crack resistance.

Cutting times are reduced due to the good chip control of efficient chips.

Achieve superior processing efficiency in the field of a wide range of steel/casting parts processing.

ZC2501 ZC2502 : Suitable for low speed machining of steel parts

ZC2511 ZC2512 : Suitable for high speed machining of steel parts

ZK3511S : Suitable for hihg speed machining of cast iron parts

2. Coated Carbide (PVD)

Good for low to high speeds and finishing for heavy rough cutting.

Stable cutting with excellent toughness.

The fine and smooth surface of the PVD coated carbide provides a good and high surface finish.

High reliability has been achieved in the field of unstable processing of stainless steel.

ZP1521 : Suitable for high speed machining of stainless steel

3.Cermet

Excellent wear resistance allowing high cutting speeds

Cermet maintains a good surface finish due to low affinity with the workpiece material.

Excellent wear resistance allowing high cutting speeds.

ZN60 : Suitable for steel/cast finishing processing

4. Carbide

Tough and hard, good thermal conductivity

Suitable for cutting non-ferrous metals and non-metals

Stable cutting at low cutting speeds, including milling operations

ZK10 : Suitable for cutting aluminum Al non-ferrous processing

5.CBN

Superior wear resistance when cutting hard materials

Suitable for high speed cutting of cast iron and sintered steel

High thermal conductivity provides stable cutting

CBN-S : Suitable for processing difficult to cut materials

CBN-K : Suitable for processing cast iron

6.PCD (Sinter diamond)

Applicable for non-ferrous metals, metal-free rotary milling and other various types of cutting.

Reduced edge build-up allows for high-precision cutting.

Various applications for cutting non-ferrous metals and non-metals.

The finished surface will be rainbow colored. (A mirror-like finished surface will not be obtained when using a single Crystal Diamond.)

PCD : Suitable for processing cast iron

5. MZG tungsten carbide inserts instructions

Safety notes for cutting tool

1. Introduction

MZG has put a "caution" label or a "warning" label on the package of the cutting tool products, but it is not on the tool itself.

Before using and handling any cutting tool products and cutting tool materials, be sure to read this guide for proper use.

Also, as part of your security education, be sure to familiarize all of your live traders with the content in this guide.

2 basic information for cutting tool materials

Technical Terms 2-1

Cutting Tool Material: Terminology for cutting tool materials, such as Cemented Carbide, Coated Carbide, Cermet, Coated Cermet, Ceramic, CBN, and PCD.

Carbide Material: Cement Carbide with WC (Tungsten Carbide) as the main component.

2-2 physical properties

Tolerance: Depends on materials (eg. Grey, Black, Gold, etc.)

Odour: None

Hardness: Carbide/Cermet 5~30GPaHV, Ceramic 10-40GPaHV

CBN 20~50GPaHV,PCD 80~120GPaHV

Sp.Gr.: Carbide 9~16, Cermet 5~9, Ceramic 2~7,CBN/PCD 3~5

Composition 2-3

Carbide, nitride, carbon nitride and oxide with W,Ti, Al, Si, Ta,B, ect. And furthermore, metal like Co, Ni, Cr,Mo are included in some cutting materials.

Caution of using the cutting tool

1. General cutting tools

Caution for using cutting tools

Precariousness: Direct touch to a sharp edge can cause injury.

Measures: When you put tools into the machine or take tools out of the box, please wear protective gloves.

Precariousness: misuse or inadequate working conditions can cause the tool to break or the broken pieces to scatter.

Measures: Use safety items, such as safety glasses and protective gloves.

Use within the range of our recommended cutting conditions. Consult our catalog or instruction manual.

Precariousness: Excessive impact or heavy wear will increase cutting resistance and may cause tool breakage and scattering of broken parts.

Measures: Use safety items, such as safety glasses and protective gloves.

Early exchange of tools is preferable.

Precariousness: Heated or prolonged chip dispersion can cause injuries or burns.

Measures: Use safety items, such as safety glasses and protective gloves.

For chip removal, please stop the machine beforehand and wear safety items such as safety glasses and protective gloves.

Precariousness: tools and materials reach high temperatures during the cutting operation. Direct contact with tools and materials shortly after cutting can cause burns.

Measures: Use safety items, such as safety glasses and protective gloves.

Precariousness: Sparks, heat generation or high temperature chips during operation can cause filing.

Measures: Do not operate around a dangerous area, where there is any possibility of fire or explosion.

In case of using oil-refrigerant, make sure there is enough fire protection equipment.

Precariousness: Lack of dynamic balance during high speed revolutions leads to vibrations that can cause the tool to break.

Measures: Use safety items, such as safety glasses and protective gloves.

Carry out the trial operation before cutting and confirm that there is no vibration or unusual sound.

Precariousness: The direct touch of the milling cutters that were generated on the rough surface of the work piece can cause injuries.

Measurements: Do not touch the workpiece with your bare hand.

2. Indexable cutting tools

Precariousness: If the insert or other parts of the tool are not installed correctly, they may fall off or break, which may cause injury.

Measurements: Clean insert pockets or fasteners before setting up insert.

Set inserts only with supplied wrench and confirm inserts or parts are fully engaged. Never use inserts or parts other than those prescribed.

Precariousness: If the inserts are clamped too tightly with supplementary tools such as pipes, etc., the inserts or the body may break.

Measures: Do not use aids such as pipes. Set up only using the supplied key.

Precariousness: When tools are used at high speed revolutions, inserts or parts may burst out of the body due to centrifugal force. When driving, please pay special handling safely.

Measurements: Use within the range of our recommended cutting conditions. The accuracy and balance of the machine shaft should be checked and adjusted regularly to prevent bearing wear due to eccentric rotation.

3. Milling cutters and other cutting tools

Precariousness: As the milling cutter has a sharp edge, direct contact with bare hands may cause injury

Measures: Use safety items, such as safety glasses and protective gloves.

Precariousness: If a cutter is out of balance, the tool can begin to vibrate. Scattering of the broken piece can cause injury.

Measurements: Use within the range of our recommended cutting conditions.

The accuracy and balance of the machine shaft should be checked and adjusted regularly to prevent bearing wear due to eccentric rotation.

4. Drilling

Precariousness – When drilling a through hole, it is possible to create a disk during the drilling procedure that can fly out of the workpiece at high speed.

This is very dangerous as the disc has sharp edges.

Measures: Use safety items, such as safety glasses and protective gloves. Also put a cover on a piece of chuck.

5. Welded tools

Precariousness: the dispersion of falls from broken inserts can cause injuries.

Measurements: Check that the cutting inserts are well welded before use.

Do not use brazed tools in conditions that require a high cutting temperature.

6. Others

Precariousness: If the welding is carried out many times, the strength of the carbide insert deteriorates and it can easily break during cutting.

Measures: Do not use tools that have been welded multiple times. The quality of the tool deteriorates.

Precariousness: tools can only be used for the proper application. It can damage tools and machines.

Measurements: Follow our recommended use for tools.

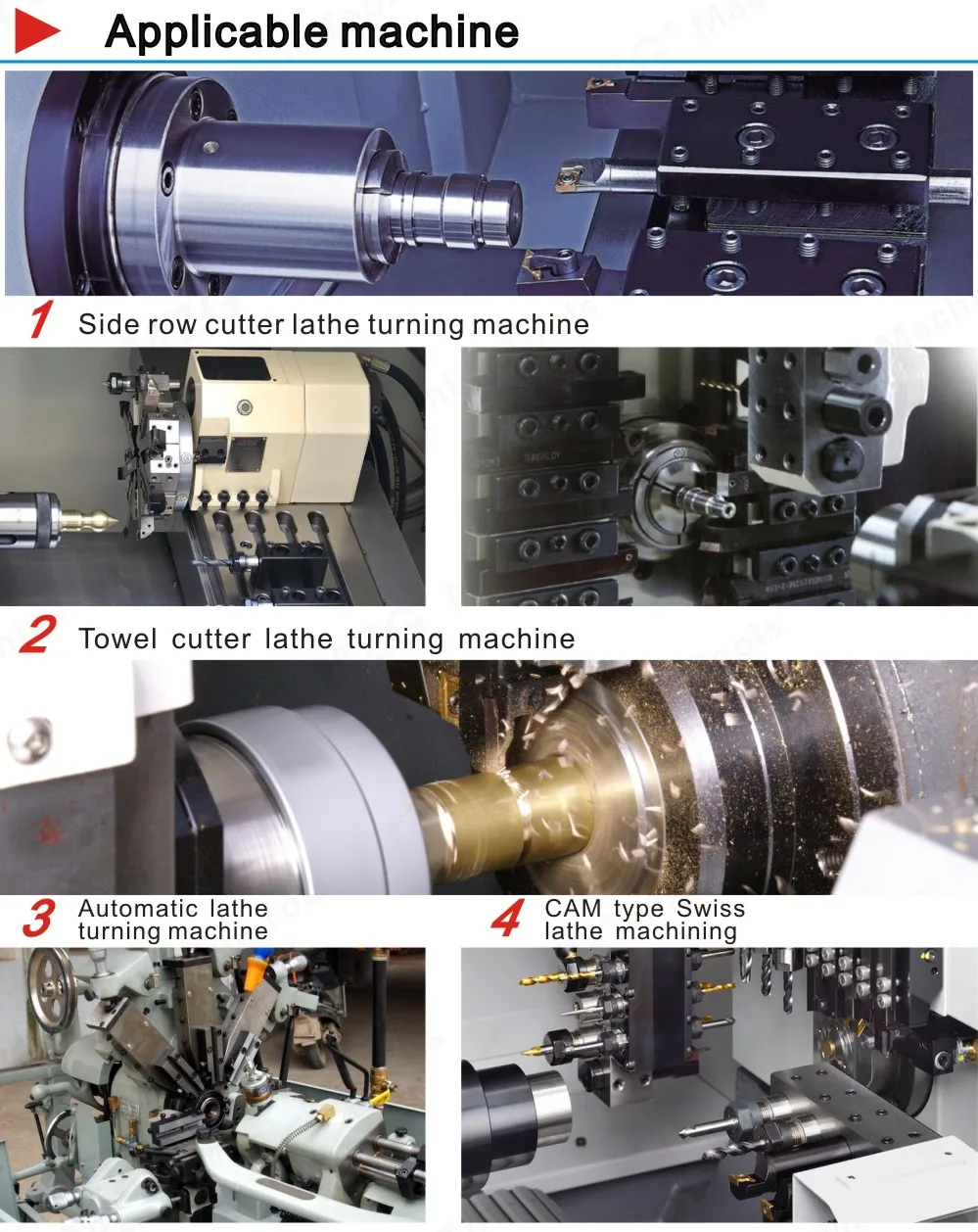

6. Application of MZG turning tool

Application machine:

turning machine,

turning machine,

automatic turning machine

Cam Type Swiss Lathe Machining

Applicable turning machine

Processing mode and samples of finished products

internal twist

external spin

grooving, cutting, face cutting

thread turning

Shallow slot machine

Small hole machining

Spin Processing Mode

Copyright@http://www.mzg.tw all rights reserved 粤ICP备10018249号

Copyright@http://www.mzg.tw all rights reserved 粤ICP备10018249号